Milestones and achievements characterize US Critical Material’s journey: In the last year, we have experienced several successful findings, a steady flow of innovations, and expansions through organic growth. The following timeline affirms our successes within a very short time frame. These are vital checkpoints as they identify breakthroughs that we are very proud of.

INL, globally recognized for its expertise in Advanced Separation Science and Engineering, serves as the U.S. Department of Energy’s primary Separation Sciences R&D Testbed. INL scientists will contribute technical expertise to ensure the pilot plant integrates cutting-edge, environmentally responsible refining processes that can scale to full production.

Key National Security Objectives:

- Reduce U.S. reliance on adversarial nations for critical minerals

- Secure a domestic supply chain for rare earths used in defense systems

- Advance mineral processing technologies essential for national resilience

Key Project Highlights:

- Pilot Plant Capacity: 1 to 2 tons of ore per day, based on a validated bench-scale flow sheet

- Objective: Demonstrate innovative mineral processing and separation technologies

- Impact: Establish intellectual property and scalable domestic production capabilities for critical materials

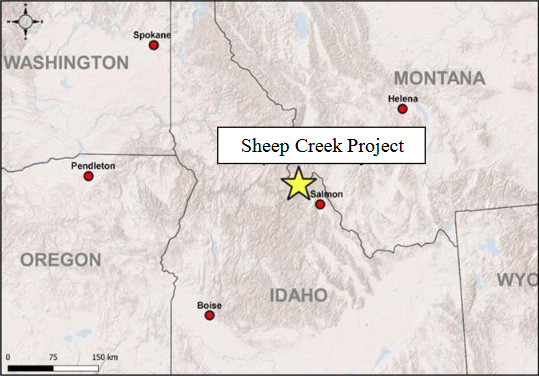

USCM began project generation in 2021 with the staking of the SC claim group, then began additional staking to acquire the current claim block. Geologic work from 2021 forward includes: 1) Airborne Geophysical surveys over a portion of the project area, 2) Geologic mapping, 3) A generative AI program over the entire property, 4) A reconnaissance-level rock, soil, and stream sediment sampling program. This exploration has identified several areas of the district that have the potential to host significant rare earth minerals that could be commercially viable.

With prime mineral claims averaging 1.2% neodymium (12,000 ppm), this announcement comes at a pivotal time as the United States faces urgent vulnerabilities across critical mineral supply chains. Neodymium is indispensable for manufacturing advanced systems essential to national defense, energy resilience, and technological innovation.

With grades approaching 9% (89,932 ppm) and combined neodymium and praseodymium concentrations of 2.4% (23,810 ppm), as measured by Activation Labs (actlabs.com), an independent geochemical and geo-metallurgical analysis lab, Sheep Creek surpasses any other known domestic resource. US Critical Materials mineral claims cover approximately 10 square miles. The initial 2.5 square mile site contains over 60 carbonatite formations, underscoring its vast potential.

Contractor in collaboration with Participant will engage in a multi-phase collaborative project to ultimately develop a process flow sheet for carbonatite ore handling, preparation, and extraction of targeted, value-added metals by invoking a combination of conventional, newly developed (within the past decade), and emerging materials handling and separations processes.

High Levels Of Gallium Confirmed At Sheep creek

US Critical Materials can confirm that INL measured grades of gallium from 180 parts per million (ppm) to 385 ppm and up to 18% (tree) total rare earth elements. "We are now able to confirm the presence of high-grade gallium at Sheep Creek. We look forward to continued work which will further develop a process to separate the gallium and other elements in an efficient and sustainable manner," stated Dr. Robert Fox, Critical Materials Business Lead for INL Energy, Environment, Science & Technology Directorate.

Phase One of the Cooperative Research and Development Agreement (CRADA) with Idaho National Laboratory (INL) has been completed.

This phase involved studying, testing, and confirming the gallium and other critical minerals content at US Critical Materials Sheep Creek Deposit.

Simultaneously, INL had a team of scientists, engineers, lab technicians, and critical mineral experts begin to explore ways to create a separation and process system for the Sheep Creek ore. The next phase is being structured to cover the next 2 years of continued development of multiple separation and processing technologies.

The US currently has no separation and processing technology, with China dominating the world's critical minerals processing.

US Critical Materials Corp. announces the successful completion of an AI-powered mineral targeting program on its high-grade rare earth elements (REE) Sheep Creek exploration property in Montana, USA. This program was part of a strategic partnership with VerAI Discoveries, a leading AI-powered mineral asset company.

"Using our geophysical data and high-grade rare earth element targets on a portion of the property, VerAI has successfully identified multiple drill-ready targets on adjacent land with similar characteristics," said James B. Hedrick, President of US Critical Materials. "From our initial evaluation of these targets, we have high confidence in their potential to host significant high grade REE mineralization and further confirms our project as a future key strategic supplier of REEs including high levels of neodymium and praseodymium, and critical minerals including scandium, gallium, strontium, niobium, and yttrium. We are currently working with Idaho National Labs to develop a US proprietary separation and processing system that will be significantly more efficient and environmentally responsible than what the Chinese are using

Electrochemical Extraction and Purification of Gallium and the full spectrum of rare earth critical minerals

The proposed recovery methodology overcomes technical barriers associated with state-of- the-art critical mineral extraction technologies including fractional precipitation and carbonation methods; commercial electrolysis methods (i.e., mercury usage); solvent extraction; and ion-exchange. The proposed EMR will use only electricity, water, and N2 gas without need for other chemical reagents to recover REE’s from the ore leachate.

The electrochemical method here is targeted at Ga, however the method is adaptable and useful for recovery of many value-add metals. Although Sheep Creek carbonatites are the target feedstock for this study, the EMR can be used on multiple critical mineral and material sources that have undergone chemical dissolution to form a metal-rich liquor.

US Critical Materials Significantly Increases Its Potential Rare Earth Reserves Through the Use of AI-driven Targeting Provided by VerAI Discoveries

INL and US Critical Materials are partnering to advance rare earth element separation technologies in the U.S., focusing on developing solutions to address the environmental issues related to mining and processing.

The increased need for rare earth elements makes finding effective, efficient and environmentally safe methods for mining and recycling them even more vital.

Expanding into a critical segment of America’s rare earths supply chain, US Critical Materials Corp. is working with Idaho National Laboratory to develop new technologies to separate this suite of notoriously tightly interlocked technology elements.

While the United States has no shortage of potential domestic rare earth supplies, and even has one producing mine in California, there are currently no commercial REE separation facilities in North America. China, which has dominated the processing and separation of rare earths for decades, continues to account for about 85% of global capacity.

With electric vehicles, wind energy, and high-tech devices creating enormous new demand for rare earth elements, there has been an increased push to develop REE separation capacity in the U.S.

This report describes the high-resolution helicopter-borne magnetic and radiometric survey

completed by Precision GeoSurveys Inc. at the Sheep Creek survey area for US Critical Materials

Corp. The Sheep Creek survey area straddles the Montana – Idaho state border. It was

flown from June 2 to June 5, 2023.

US Critical Materials has nearly nine percent, 9 % TREO (89,932ppm), far ahead of any other domestic rare earth resource. The deposit also has readings of 2.4% (23,810ppm) combined neodymium and praseodymium, which are both essential for the green economy. US Critical Materials has recently confirmed carbonatite mineralization at depth, below high-grade surface samples of 17.05% TREO and 16.44% TREO. The Sheep Creek, Montana, property under claim by US Critical Materials totals seven (7) square miles.

One characteristic that sets Sheep Creek apart from most other rare earths projects in the U.S. is the fact that significant mineralization has been accessed and sampled underground via pre-existing mine workings.

US Critical Materials has recently confirmed mineralization at depth below high-grade surface samples of 17.04 % TREO and 16.44% TREO. Based on the presence of mineralization at depth, the technical team intends to focus exploration efforts on these promising zones. Two of three historic adits, Adit #3 and Adit #1, have been successfully opened and sampled Rare earth samples taken from 125 feet below ground in the adits confirm over 10% (100,000 ppm) of total rare earth oxides, (TREO) including high levels of neodymium and praseodymium. These rare earth readings far exceed any other domestic rare earth resource. The results included channel samples from 2 underground adits (tunnels) that were unsealed in October 2022 and sampled in November 2022. These adits are dug up to 400 feet horizontally and are 125 feet below the surface. The analytical results were obtained from Activation Labs, Ancaster, Canada. Results from opening, mapping, and sampling of the underground workings will support the filing of a Plan of Operation with the U.S. Forest Service for summer 2023 drilling.